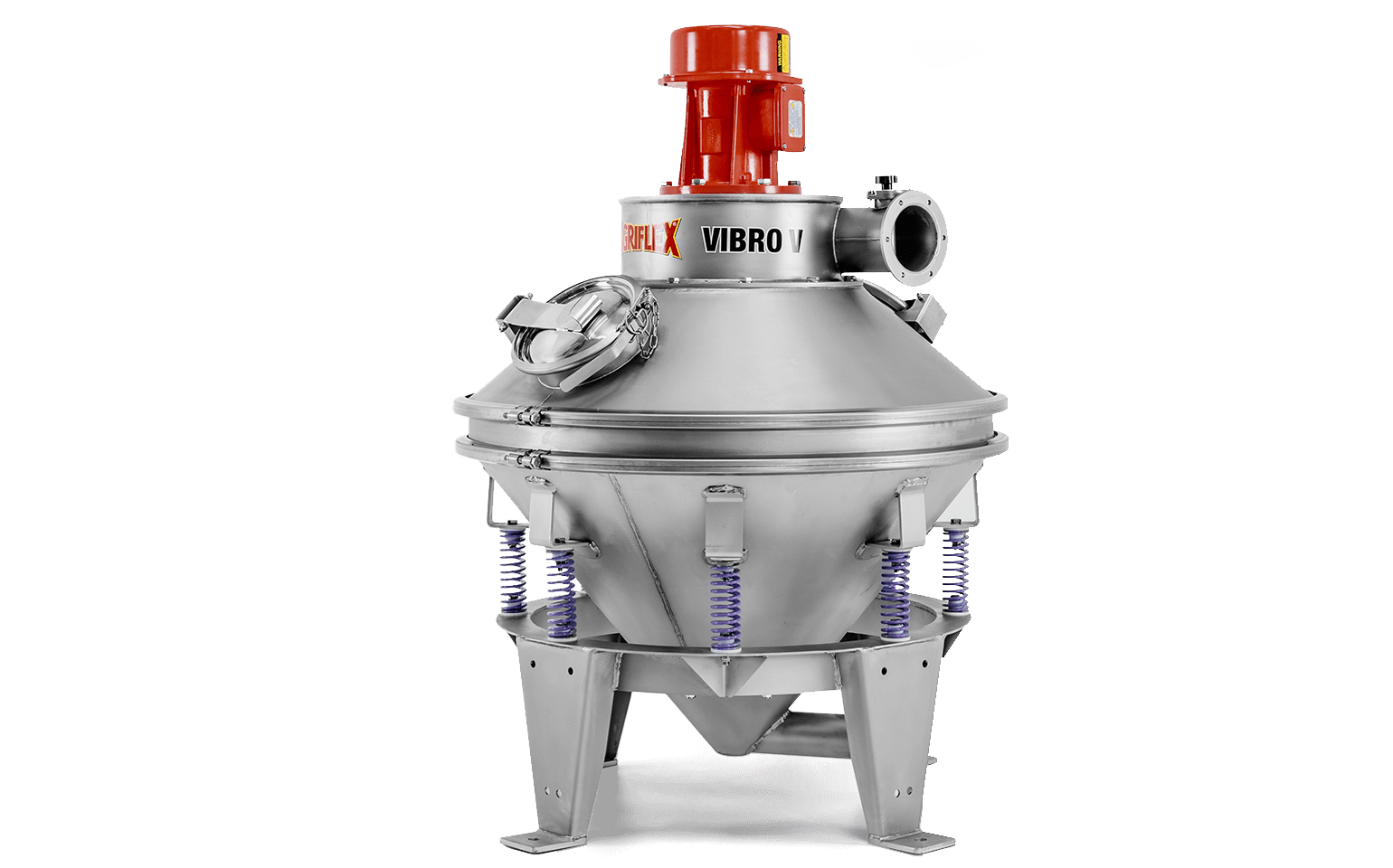

The vibrating sifter is an accessory system for sieving powdered food products while capturing foreign bodies. Positioned on the pneumatic or gravity-loaded line, the system allows for the thorough cleaning and sanitising of flour and food powders, even in ATEX zones.

Advantages

Safety

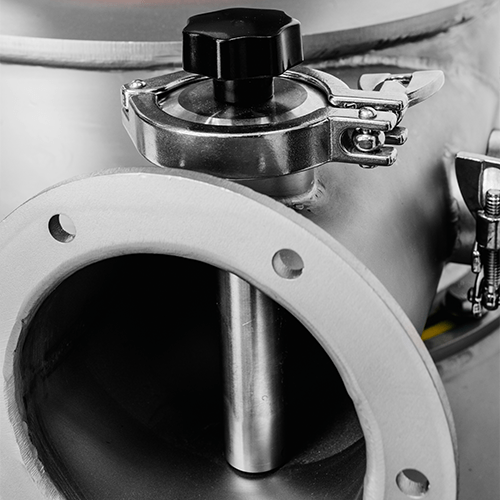

Guaranteed iron removal with the use of two (diametrical and orthogonal) inlet magnetic rods. The inlet conduit (where the magnets are housed) is an expansion conduit, which slows down the incoming product and improves the pick-up of foreign bodies.

Double-effect sifting

Passage through the mesh is rapid even with fine meshes, avoiding the accumulation of product on the sifting mesh and the consequent mechanical stress on it. The double effect consists of a vibrator at the top of the attachment that generates the first sifting effect of the mesh and 50 balls (Ø 40 mm made of food-grade plastic) that are placed between the sifting mesh and the perforated safety plate, to ensure further movement.

Easy cleaning and inspection

Thanks to a quick-release system for the extraction of the two magnets and the double hatch that provides good visibility over the entire surface of the sifting mesh – also equipped with a quick-release lever – the structure allows easy inspection and cleaning of the outside and inside of the sifting mesh.

DOWNLOAD DATA SHEET

(PDF, ~250Kb)