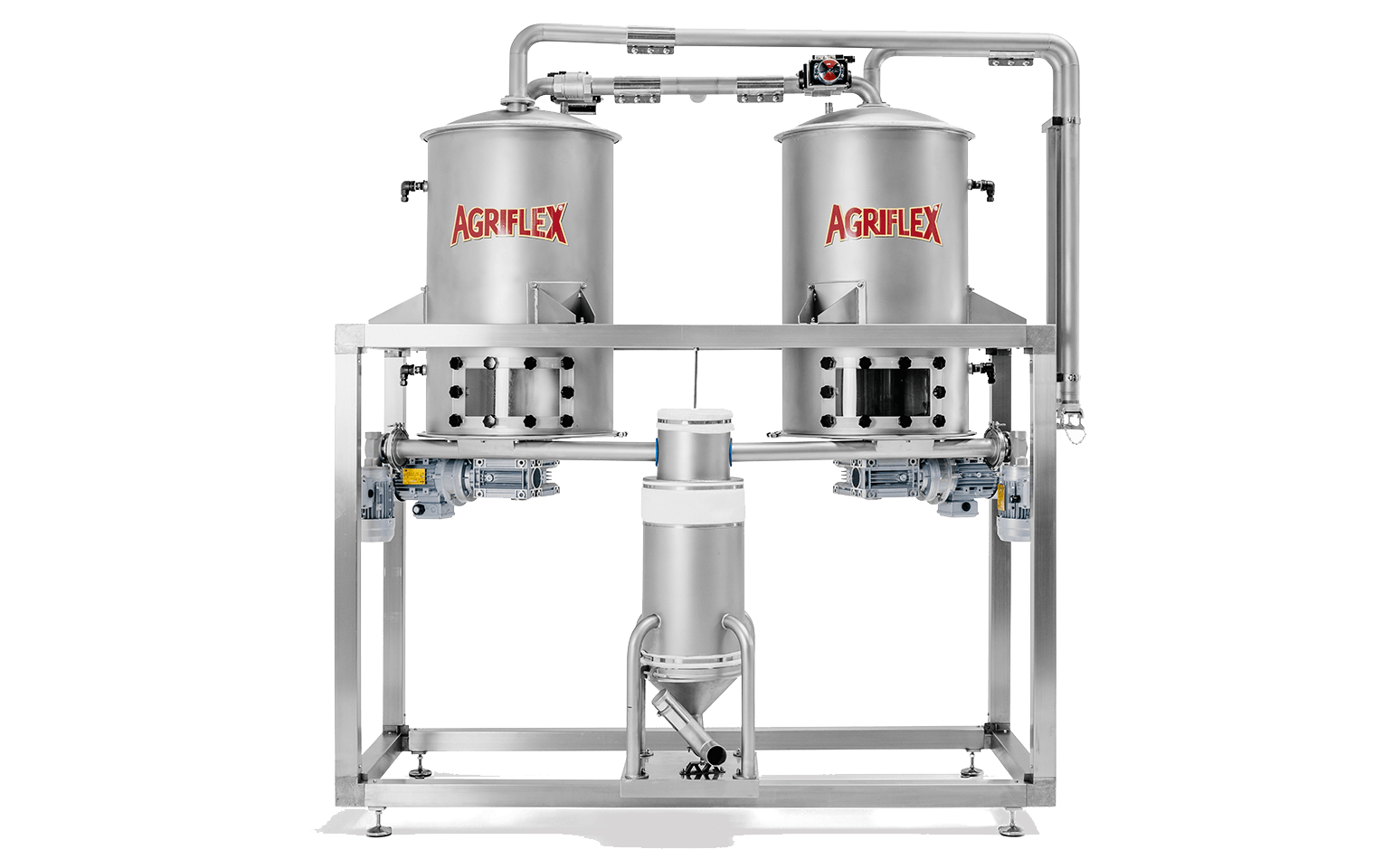

Designed and produced according to specific customer requirements, they are particularly suitable for the biscuit, bakery, confectionery and food industries in general. Generally characterised by three stages – loading into the container, dosing and transport to the point of use – the handling of micro-ingredients can be fully automated, manual or semi-automated The micro-dosing unit can be composed of several containers, each adapted according to the characteristics of the ingredients.

Advantages

Simplicity and integration

Automated dosing systems do not require skilled labour and integrate seamlessly with the main plant.

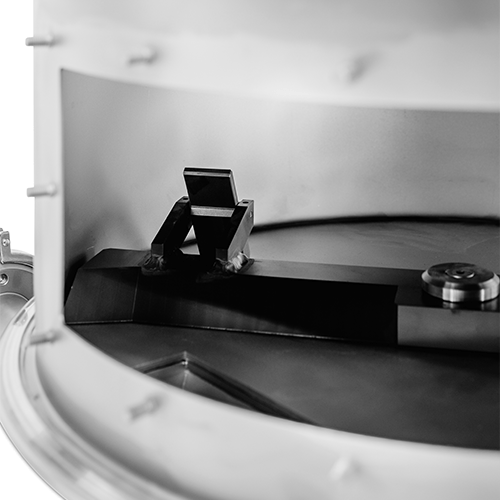

Precision and savings

High integration with the main plant and high automation allow fast dosing, savings in handling, accurate traceability and reduction of human errors.

Control

Maximum dosing precision in the execution of the required recipes and consequent minimisation of raw material waste.

DOWNLOAD DATA SHEET

(PDF, ~350Kb)