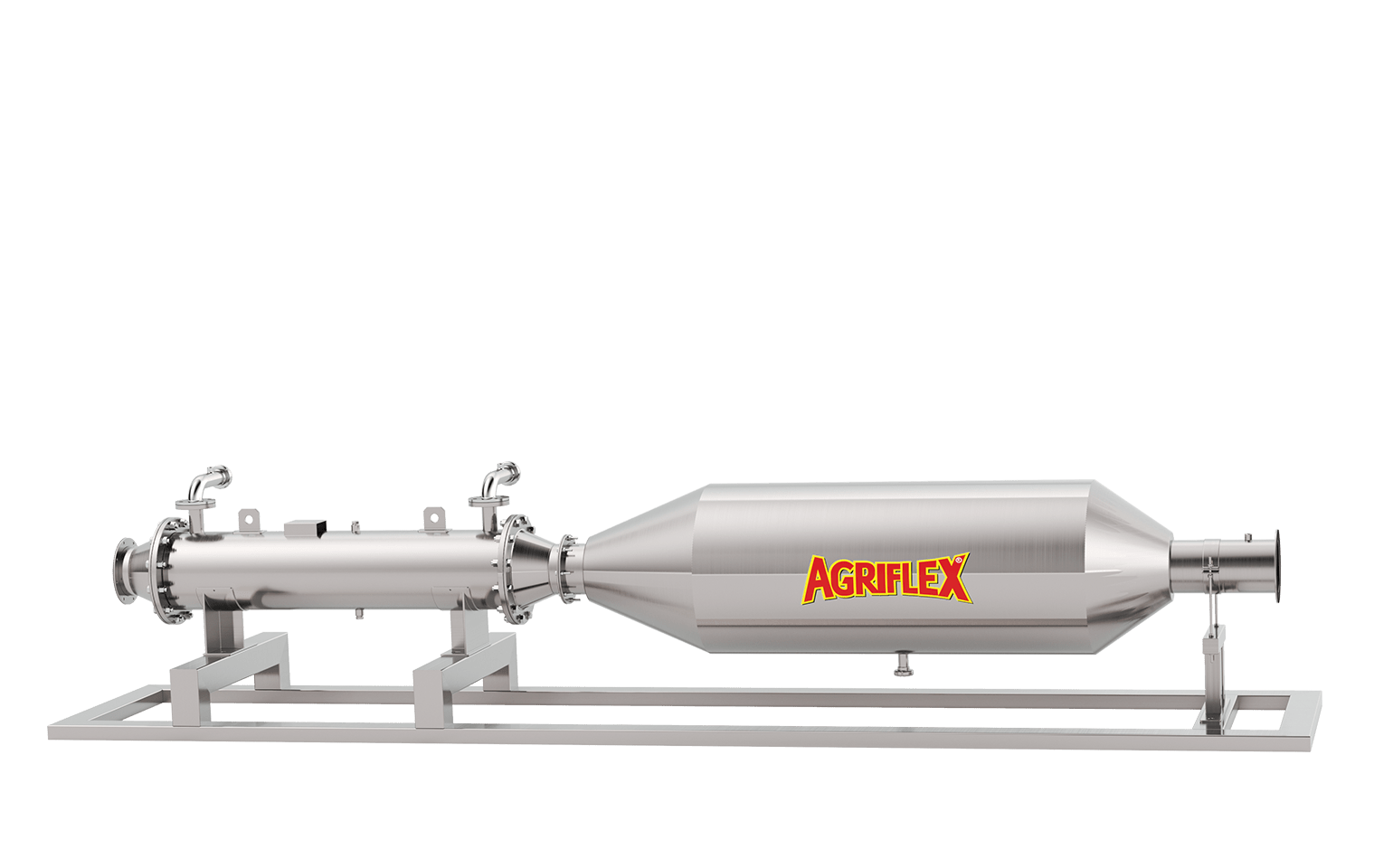

Consisting of two units – a shell and tube air cooling unit and a handling unit -, in the cooling and dehumidification system the pressurised air is channelled through the heat exchanger, where it comes into contact with a circuit in which the refrigerant circulates. The air then undergoes the progressive condensation of the humid part along the path inside the exchanger. Subsequently, the appropriately structured air handling unit separates and drains all residual condensate. At the outlet of these two systems, completely dried cold air is thus obtained.

Advantages

No mixing

Thanks to the closed circuit, the raw materials are not mixed with ice or other cooling elements, thus being fully compliant with the recipe and meeting health and hygiene regulations.

No thermal stress

With the self-regulating system, temperatures are always constant and controlled. As a result, the system does not cause risky and detrimental thermal stress to the flour and – consequently – to the dough.

Simplicity and efficiency

The system is extremely economical in terms of energy consumption, and thanks to its ease of use, it does not require skilled labour.

DOWNLOAD DATA SHEET

(PDF, ~350Kb)