Case history

Un’eccellenza italiana in ambito di prodotti da forno surgelati su scala industriale che ha implementato i nostri sistemi di automazione degli ingredienti, raggiungendo un livello d’avanguardia nel settore, in Italia e nel mondo

San

Giorgio

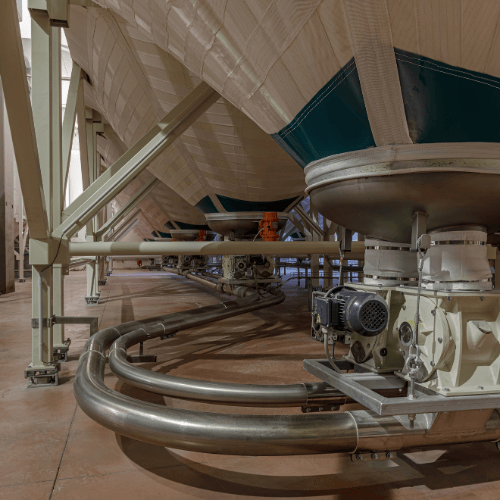

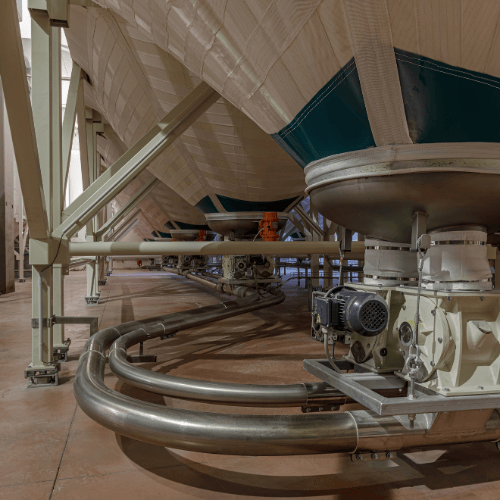

We would like to present one of our latest projects carried out at the San Giorgio Spa plant, in the province of Salerno. In this case, we will illustrate how the adoption of Agriflex systems in the field of storage, dosing and fermentation has led to a considerable reduction in procurement times and “real-time” control of the entire raw material handling process.

Case history

San

Giorgio

An Italian excellence in the industrial confectionery sector, in Italy and in the world, which has implemented industrial fermentation systems for natural leavening applied to its products.

We would like to present one of our latest projects carried out at the San Giorgio Spa plant, in the province of Salerno. In this case, we will illustrate how the adoption of Agriflex systems in the field of storage, dosing and fermentation has led to a considerable reduction in procurement times and “real-time” control of the entire raw material handling process.

Interview

We asked Vincenzo Carpentieri – Quality Control Manager – some questions about the company’s requirements and how the Agriflex solutions adopted have supported production improvement.

What is the history of San Giorgio, what are the main products you make, and with which production cycle?

Our story begins in the 1980s and is first and foremost the story of Bruno Sabato who has transformed, in 35 years, a small pastry shop in Castel San Giorgio, on the outskirts of Salerno, into a large croissant company, specialising in the food service market: San Giorgio Dolce & Salato. With commitment and dedication, the small laboratory of the origins has become one of the largest confectionery factories in Italy, that produces excellence. Sabato’s passion, shared by his sons Antonino, Ivan and Alessandro, along with the latest generation production and storage plants, is the company’s continuous growth foundation. To satisfy every need, we offer more than 500 sweet and savoury products, including vegan and gluten-free: from ready to be pre-processed, from pre-cooked to those to be leavened. Our innovative production site of over 90,000 square metres has 17 production lines and state-of-the-art packaging plants.

What are the main distribution channels for San Giorgio products?

We operate with over 250 HO.RE.CA. (Hotel-Restaurant-Cafè) distributors worldwide throughout the country, as well as having a direct distribution in the province of Salerno. We have started this year to serve Italian whole sales distribution customers, while abroad we are present through importers in North America, Australia, Europe and South Africa.

How does the company position itself concerning the competition?

Our products are recognized for superior quality, despite a price positioning in line with the market.

How does San Giorgio guarantee its products quality?

We carry out over 25,000 audits annually and are BRC, IFS and ISO certified to ensure the quality and safety of all our products.

What criteria are applied in the raw material selection?

We collaborate with the leading European suppliers in the industry, conducting thorough screening to identify the best ones in terms of product quality.

Qual era la principale necessità/problematica da soddisfare e che vi ha spinto ad adottare le soluzioni Agriflex?

Ci siamo rivolti ad Agriflex per il miglioramento delle nostre fasi produttive legate alla conservazione ed al dosaggio automatico delle materie prime.

Quali vantaggi avete riscontrato nell’utilizzo delle soluzioni di stoccaggio e dosaggio e fermentazione di Agriflex per la produzione dei vostri prodotti?

Le soluzioni Agriflex hanno consentito tutta una serie di vantaggi: riduzione dei tempi di approvvigionamento, riduzione del numero di operazioni manuali, controllo real time del processo. Hanno supportato inoltre il processo di miglioramento continuo della qualità e della riduzione degli sprechi delle materie prime, con una diminuzione significativa delle operazioni manuali e un impatto notevole sul miglioramento dell’efficienza produttiva.

In che modo la sinergia creata con Agriflex si adatta alle nuove tendenze del mercato e all’innovazione tecnologica?

Agriflex si è rivelato il partner ideale in termini di ricerca continua dell’eccellenza e dell’innovazione che caratterizzano da sempre San Giorgio.Siamo convinti che la partnership con Agriflex supporterà il percorso di miglioramento continuo della San Giorgio nella sua strategia di crescita a medio/lungo termine e siamo fieri di avere individuato in Agriflex un partner ideale che condivide con noi i valori dell’eccellenza e dell’innovazione.

Ringraziamo la famiglia Bruno e l’azienda San Giorgio per la proficua collaborazione.

San Giorgio Spa | Via G. Petti 10/2 | Località Castel San Giorgio | Salerno (SA) – ITALY | Tel. +39 081 9535125 | info@sangiorgiospa.eu